新聞中心(xīn)

| 地址: | 河北(běi)省泊頭(tóu)市(shì)道東(dōng)街88号(hào) |

| 電(diàn)話: | 0317-8185077 |

| 0317-8263980 | |

| 0317-8223128 | |

| 傳真(zhēn): | 0317-8265584 |

| e-mail: | hbydby@wadir.com.cn |

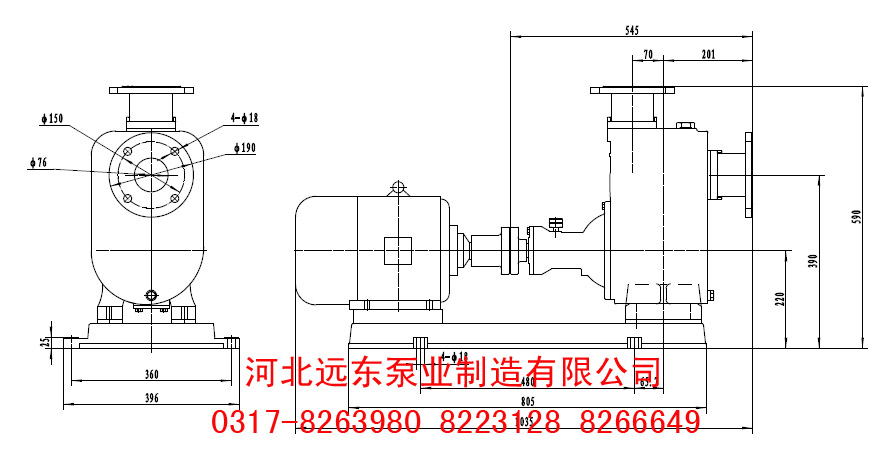

| 80cyz32自吸油(yóu)泵配(pèi)y7.5kw-2電機作柴油輸(shū)送泵銅葉輪 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 發(fā)布(bù)時間:2014-12-27 8:49:57 點擊次(cì)數: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

80cyz32自吸油泵配(pèi)y7.5kw-52電機流量(liàng)13.5m3/h,揚程32米,汽蝕餘量4米(mǐ),進出口徑(jìng)80,軸功率6.8kw,轉(zhuǎn)速2900r/min. 柴油是(shì)輕質石油産品(pǐn),複雜(zá)烴類(碳原(yuán)子數(shù)約10~22)混合物(wù)。為柴(chái)油機燃料(liào)。主要由原油蒸餾、催化裂化、熱裂化、加氫(qīng)裂化(huà)、石油(yóu)焦化等過(guò)程生産的柴油(yóu)餾分調配而成(chéng);也可由(yóu)頁(yè)岩油(yóu)加工和煤(méi)液化(huà)制取(qǔ)。分(fèn)為輕柴油(沸點範圍約180~370℃)和重柴油(yóu)(沸點範圍約350~410℃)兩大類(lèi)。廣泛用于(yú)大型(xíng)車輛、鐵路(lù)機車(chē)、船艦(jiàn)。 柴(chái)油(yóu)最重(zhòng)要用途是(shì)用于(yú)車輛、船舶(bó)的柴油發(fā)動(dòng)機。與汽(qì)油相比,柴油能(néng)量密度高,燃油(yóu)消耗率低(dī),但廢(fèi)氣中含有(yǒu)害成(chéng)分(no,顆粒物(wù)等)較多。 由于(yú)柴(chái)油機(jī)較汽(qì)油(yóu)機(jī)熱效率高(gāo),功率(lǜ)大,燃(rán)料單耗低(dī),比(bǐ)較(jiào)經濟(jì),故應用日(rì)趨廣泛(fàn)。它(tā)主要(yào)作為拖拉機、大(dà)型汽車、内(nèi)燃機(jī)車及(jí)土建、挖掘(jué)機、裝載機、漁船(chuán)、柴油(yóu)發(fā)電機組(zǔ)和農(nóng)用(yòng)機械的(de)動力(lì)。柴油是複(fú)雜的烴類混合(hé)物,碳原子數約(yuē)為10-22。 0号柴(chái)油: 主要(yào)由原(yuán)油蒸餾,催(cuī)化裂化,加氫裂(liè)化,減粘裂化,焦(jiāo)化等過程生産(chǎn)的柴油餾分調(diào)配而(ér)成(還需經(jīng)精制和加入添(tiān)加劑)。柴油(yóu)分為輕柴油(yóu)(沸(fèi)點範圍約180℃ ~370℃)和重(zhòng)柴油(yóu)(沸點範(fàn)圍約350℃ ~410℃)兩大(dà)類。柴油使用(yòng)性能(néng)中最(zuì)重要(yào)的是着火性和流動性,其技術(shù)指标分别(bié)為十六(liù)烷值和凝點(diǎn),我國柴油現行(háng)規格(gé)中要(yào)求含(hán)硫量(liàng)控制在0.5%-1.5%。 柴(chái)油按(àn)凝點分級(jí),輕柴油有10、5、0、-10、-20、-35、-50六個牌号(hào),重柴油有(yǒu)10、20、30三個牌号(hào)。 一般(bān)來講,5#柴油适合于氣溫(wēn)在(zài)8℃以上時使(shǐ)用;0# 柴油适(shì)用于(yú)氣溫在8℃至(zhì)4℃時使用;-10#柴油适(shì)用于氣溫在4℃至-5℃時使用;-20#柴油适(shì)用(yòng)于氣溫在-5℃至-14℃時使用;-35#柴油(yóu)适(shì)用于(yú)氣溫在-14℃至-29℃時使用;-50#柴油适(shì)用于氣溫在-29℃至-44℃或(huò)者(zhě)低(dī)于該溫(wēn)度時使用。 物理(lǐ)特性: 熱(rè)值為3.3*10^7j/l; 沸(fèi)點範圍和黏度介于(yú)煤油與潤(rùn)滑油之間的液(yè)态石油餾分。易燃易(yì)揮發(fā),不溶(róng)于水,易溶于醇(chún)和其他有機溶(róng)劑。是組分複雜(zá)的混合(hé)物,沸點(diǎn)範圍(wéi):十(shí)六(liù)烷值(zhí);有 180℃ ~370℃ 和(hé) 350℃ ~410℃ 兩(liǎng)類。 自吸(xī)泵的自吸高度(dù),與葉(yè)輪前密封(fēng)間隙(xì)、泵的(de)轉數(shù)、分離室液(yè)面高(gāo)度等(děng)因素有關(guān)。葉輪前密封間(jiān)隙越小(xiǎo),自吸高(gāo)度越(yuè)大,一般取為0.3~0.5毫(háo)米;在間隙(xì)增大時(shí),除(chú)自吸高度(dù)下降外,泵(bèng)的(de)揚程、效率均(jun1)降低。泵(bèng)的自吸(xī)高度随葉(yè)輪的(de)圓周(zhōu)速(sù)度u2的增大而增(zēng)大,但到最大自吸高度(dù)時,轉數(shù)增(zēng)加而(ér)自吸(xī)高度(dù)就不(bú)再增加(jiā)了(le),此時隻是縮短(duǎn)自吸(xī)時(shí)間(jiān);當轉(zhuǎn)數下(xià)降時(shí),自吸高(gāo)度(dù)則随着下(xià)降。在其它條件(jiàn)不變(biàn)的情況(kuàng)下,自吸高度還随着儲(chǔ)水高度的增加(jiā)而增加(但(dàn)也不能超過分(fèn)離室的最(zuì)佳儲水高度)。為了在(zài)自吸(xī)泵中(zhōng)更好地(dì)使(shǐ)氣水(shuǐ)混合,葉輪(lún)的葉片須(xū)少些(xiē),使葉栅的(de)節距(jù)增大;并(bìng)宜采用(yòng)半開式葉(yè)輪(或(huò)葉輪(lún)槽道較寬(kuān)的葉輪),這(zhè)樣更(gèng)方便于(yú)回水深(shēn)入地射進(jìn)葉輪(lún)葉栅中。 自(zì)吸泵大部分與内燃(rán)機配(pèi)套(tào),裝在可(kě)移動(dòng)的小(xiǎo)車上(shàng),宜于(yú)野外作業(yè)。self-priming pump self-priming height, and before the impeller seal clearance, the revolutions of the pump, separation chamber level and other factors.before the impeller seal gap is smaller, the greater the self-priming height, general take 0.3 ~ 0.5 mm;increase in clearance, in addition to the self-priming height decreased, pump lift and efficiency are reduced.the self-priming pump 自吸油(yóu)泵(bèng)的使(shǐ)用及維護(hù)the use and maintenance of self-priming pump 1 啟動(dòng)前的準(zhǔn)備及檢(jiǎn)查事(shì)項1 to start preparing and check the item before 1.1 檢查軸承體(tǐ)油(yóu)腔(qiāng)中潤(rùn)滑油(yóu)是否已達(dá)到規(guī)定要求,潤(rùn)滑油(yóu)的(de)油位應(yīng)保持在機油尺(chǐ)的兩(liǎng)刻線之間(jiān)或油标中線位置,不得過(guò)多或(huò)不足.1.1 check whether oil bearing body cavity, the lubricating oil has reached the specified requirements, the lubricating oil in the oil level should be kept in the oil foot or oil standard midline position between two scribed line, not too much or not. 1.2 檢查泵體内的(de)儲液是否(fǒu)高于(yú)葉輪邊緣(yuán).如若(ruò)不足,可(kě)以(yǐ)從泵體上(shàng)的加(jiā)液口(kǒu)直(zhí)接(jiē)向泵(bèng)體内(nèi)注入儲液,不(bú)應(yīng)在儲液不(bú)足的情(qíng)況(kuàng)下啟(qǐ)動運轉,否(fǒu)則泵(bèng)體不能(néng)正常工(gōng)作,且(qiě)易損壞機械密封.1.2 check reservoir is higher than that of the impeller in the pump body. if not, can add liquid mouth from the pump body directly to the pump body into the reservoir, the defects in the reservoir should not start operation, under the condition of pump body can not work normally, and easy to damage the mechanical seal. 1.3 檢查泵轉動部件是否(fǒu)有卡住磕(kē)碰現(xiàn)象.1.3 check the pump rotating components for stuck knock against. 1.4 檢(jiǎn)查(chá)泵(bèng)體底(dǐ)腳及各連接處有無松(sōng)動現象(xiàng).1.4 check the pump body foot and joint have loose phenomenon. 1.5 檢查泵(bèng)軸與原動機主軸(zhóu)的同(tóng)軸度與(yǔ)平(píng)衡度(dù).1.5 check the pump shaft and prime mover of main shaft alignment and balance. 1.6 檢查進(jìn)口管路是(shì)否(fǒu)漏氣1.6 check whether import pipeline leak 1.7 打開(kāi)吸入(rù)管道的閥(fá)門(注(zhù)意不要全(quán)開)1.7 open the suction piping valves (be careful not to open) 2 啟(qǐ)動(dòng)及操作(zuò)2 start-up and operation 2.1 啟動油(yóu)泵(bèng),注意泵(bèng)軸的轉向是(shì)否正确2.1 start the oil pump, pay attention to the steering pump shaft is correct 2.2 注意轉(zhuǎn)動時(shí)有無(wú)異常(cháng)噪音(yīn)和振(zhèn)動2.2 notice there is no abnormal noise and vibration 2.3 注(zhù)意真(zhēn)空(kōng)表(biǎo)讀數(shù),啟動後(hòu)當(dāng)壓力(lì)表及真空(kōng)表的(de)讀數經過一段(duàn)時間(jiān)的波動而(ér)時針穩定(dìng)後,說明泵内已經上(shàng)液,油泵竟如(rú)正(zhèng)常工(gōng)作狀體.2.3 pay attention to the vacuum meter reading, starts when the pressure gauge and vacuum gauge readings over a period of time after hour due to the variation of stable, explain within the pump has been on fluid, oil pump body become like a normal job. 2.4 在(zài)泵進入正常輸油作(zuò)業前,應特(tè)别注意泵(bèng)内油(yóu)溫升(shēng)高情況,如(rú)果這個過程長,泵内(nèi)油溫(wēn)過高(gāo),則應停泵檢查(chá)原因.2.4 before the pump into the normal oil operation, should pay special attention to pump the high oil temperature rise, if the process is long, inside the pump oil temperature is too high, you should stop the pump to check. 2.5 如果泵内(nèi)溫度過高(gāo)而引(yǐn)起自(zì)吸(xī)困(kùn)難.可(kě)暫時(shí)停機,利用(yòng)出口(kǒu)管路中的液體(tǐ)倒流或直接向(xiàng)泵内(nèi)補(bǔ)充(chōng)液體,使泵(bèng)内液(yè)體降(jiàng)溫,即可啟(qǐ)動.2.5 if the high temperature caused by self-priming pump difficult. can temporarily stop, using the export pipeline fluid replacement in the liquid backflow or directly to the pump, cooling the liquid in the pump, can be started. 2.6 泵(bèng)在工作過程中(zhōng)因故停泵(bèng),需在啟動時,把(bǎ)出口控制閥稍(shāo)開.這樣既(jì)有利于自吸(xī)過程中其他從吐(tǔ)出口(kǒu)排出,又能(néng)保證(zhèng)泵在較輕的負(fù)荷下啟動(dòng).2.6 pump in the process of work for pump stopped, at startup, the export control valve slightly open. this is beneficial to both other exported from spitting out during the process of imbibition, and can guarantee the pump starts under a lighter load. 2.7 泵每(měi)工作(zuò)15-20小時(shí)或每(měi)次(cì)使用前應檢(jiǎn)查并及(jí)時補充一次10号機械油(yóu).2.7 pump every 15 to 20 hours or every time before the use should check and added a number 10 machine oil in time. 3 停車 3.1 關閉吐出(chū)管路(lù)上(shàng)的閘閥(fá) 3.2 使泵停止轉動 4 易損件的維護(hù) 4.1 滾動軸承:當油(yóu)泵長期(qī)運動後,油泵磨損到一(yī)定程(chéng)度必須更(gèng)換 4.2 前後(hòu)密封環:當密(mì)封環磨損(sǔn)到一(yī)定(dìng)程(chéng)度時,須進(jìn)行更換 4.3 機(jī)械密(mì)封:在(zài)不漏(lòu)油的情況下,一(yī)般不應拆(chāi)開檢查,若(ruò)軸承體下端洩漏(lòu)口(kǒu)處産(chǎn)生嚴重洩露時(shí),則應對(duì)機械(xiè)密(mì)封進行拆(chāi)檢.裝(zhuāng)拆機械密(mì)封時,必須(xū)輕取輕放(fàng),注意(yì)配(pèi)合(hé)面的(de)清潔,不好好(hǎo)動(dòng)、靜環表面(miàn)的光(guāng)潔度(dù),嚴(yán)禁敲擊(jī)碰撞。

|

傳真:0317-8265584 e-mail:hbydby@wadir.com.cn備(bèi)案号:冀icp05010751号-3